MR trolleys are suitable for harsh or outdoor applications and easily couple with NER/ER large capacity hoists for the heaviest lifting and traversing requirements. Features include thermal motor protection, side guide rollers for smooth operation and plug in electrical connections.

Rubber bumpers are standard on all motorized trolleys to provide protection from collisions.

MR trolleys include four ball bearing supported side guide rollers that contribute to smooth trolley motion and reduce wear of the wheels and beam.

Most models are certified and listed to UL 1340 “Standard for Hoists.”

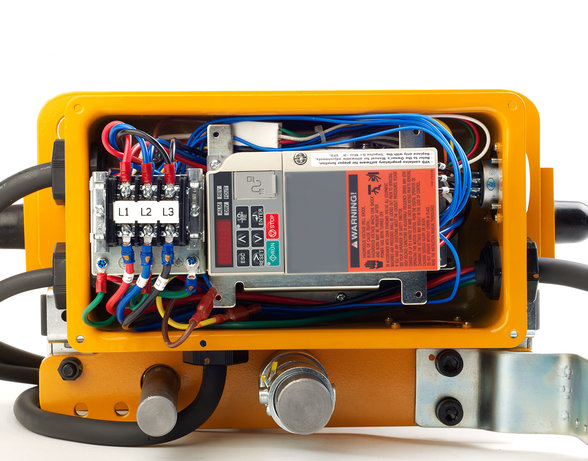

Get excellent traversing motion and load control with a variable frequency drive (VFD) on dual speed MR trolleys. The programmable VFD provides gradual starts and stops to reduce unwanted movement while travelling.

Sending...