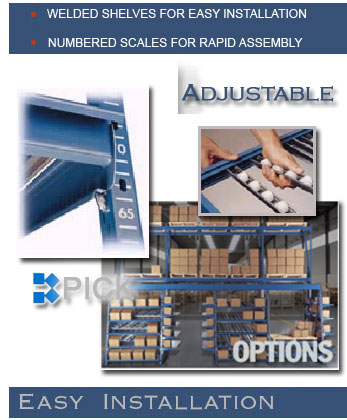

UNARCO KPICK – Kingway style carton flow is a welded shelf assembly for easy installation.

The benefits of the KPICK shelving system is ease of installation. An engineered design arrives at the jobsite fully assembled and installed in no time. UNARCO Engineering can help design sizes for depth and width of shelves to fit into the pallet rack and the sturdy construction will work in your carton flow application for years to come.

UNARCO’s KPICK, Kingway Carton Flow Design system is a welded shelf carton flow rack system that installs easily on-site with no special tools. Due to the KPICK design, installation is a snap. Complete carton flow shelf units drop into place with a sturdy clip and carton flow tracks snap in to form lanes that fit your carton sizes.

The KPICK Kingway carton flow system is very versatile and shelves adjust in 2″ increments. This flexibility allows you to reconfigure your carton flow rack system as SKU sizes change or are added and deleted.

There are no electrical parts to fail with the KPICK – Kingway carton flow design because it is powered by gravity. Loads flow automatically down the sloped shelves to the pick position. As one carton is removed, another flows forward to the front to fill the empty space. The separation of a pick aisle and a loading aisle is beneficial to warehouse efficiency.

Single-level carton flow rack systems can be engineered to effectively separate fast-moving and slow-moving stock units. Multi-level pick module systems can be used to maximize floor space as it is often more sensible to expand vertically.

UNARCO offers a variety of drop-in lanes for any carton flow application, including the Dura-Flo D2 continuous bed of rollers and RhinoDeck aluminum full-width roller carton flow.

Sending...